In Part I of this blog series, we give a brief history of Additive Manufacturing (AM), as well as some of the obstacles that are still holding AM back. Everyone is excited about the potential of this technology, but it’s quite a different thing to have sufficient confidence in repeatable production of reliable parts, for critical applications. To meet these challenges, VEXTEC’s computational platform, centered around VPS-MICRO® durability software, is being utilized to evaluate AM’s effects on three conditions that are critical to durability performance: microstructure, residual stresses, and surface roughness.

- Microstructure : In its most basic sense, a material’s microstructure is the DNA that describes how the material will behave. VPS-MICRO’s mechanistic modeling approach accounts for the variability in key microstructural parameters. This makes it ideally-suited for the AM process, where microstructure is heavily dependent upon the printer machine’s parameter settings (scan speed, layer thickness, laser power, hatch spacing, etc.).

- Residual Stresses : Depending on their post-build processes, AM-built components can exhibit significant and complex residual stresses. This is due to the directionality of the layer-by-layer printing, and the subsequent cooling/solidification kinematics. VPS-MICRO can explicitly incorporate residual stress profiles in its computational framework, allowing for accurate definitions of localized stress states.

- Surface Roughness : Part of the attractiveness of AM is that the part can be built in its near-net shape, so little or no machining is necessary. An as-manufactured AM surface is rough by nature, and this roughness takes the form of a microstructurally-thin layer of stress concentration at all points along the surface (analogous to a surface after having experienced corrosion). Recent enhancements to VPS-MICRO provide modeling of these variations in stress concentration along a part’s surface.

VPS-MICRO for Certification of Structural Aerospace Components Built by AM

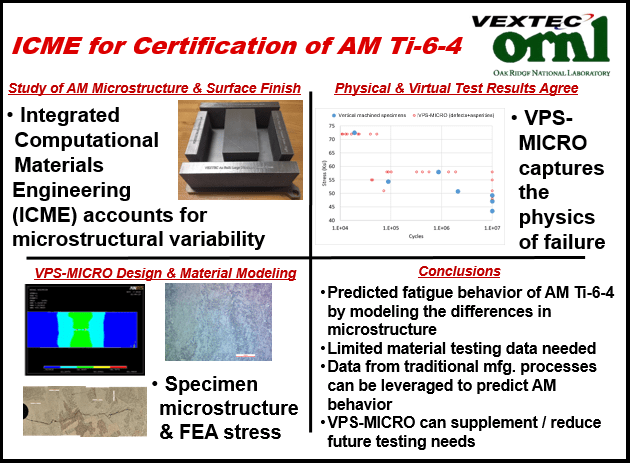

VEXTEC is collaborating with Oak Ridge National Laboratory (ORNL) on a NAVAIR-funded project to develop a computational material engineering software tool. The goal is to decrease the time and money needed to certify an AM-built structural component exposed to fatigue loading. Certification is an important obstacle to overcome, for widespread adoption of AM technology to occur in any industry. VEXTEC’s VPS-MICRO software tool for AM uses all available data and information to develop the material models. These models are computational and physics-based, and can predict other materials and microstructures to extrapolate outside of the test database. The material models are probabilistic, to predict the tails of the distributions that actually govern minimum properties. The models can be updated as more data and knowledge become available.

The computational tool integrates AM process information, material properties, computational models and microstructural damage tolerance simulations into the design and material certification process. VEXTEC’s toolbox of previously-developed software modules assesses the durability of parts processed by traditional methods of casting, forging, rolling, machining and welding. Additional modules have been more-recently developed to determine the durability of sophisticated methods such as powder metallurgy, single-crystal fabrication, and additive methods like Electron Beam Melting (EBM). In this project, the VEXTEC/ORNL team is using the tools to simulate the static and cyclic strength tests that are needed to certify EBM-produced titanium alloy Ti-6Al-4V. The program demonstrates a proof of concept capability: evaluating the variabilities in processing, geometry (surface finish) and microstructure, and their contributions to the uncertainty in durability.

VPS-MICRO to Predict AM Processing Variabilities

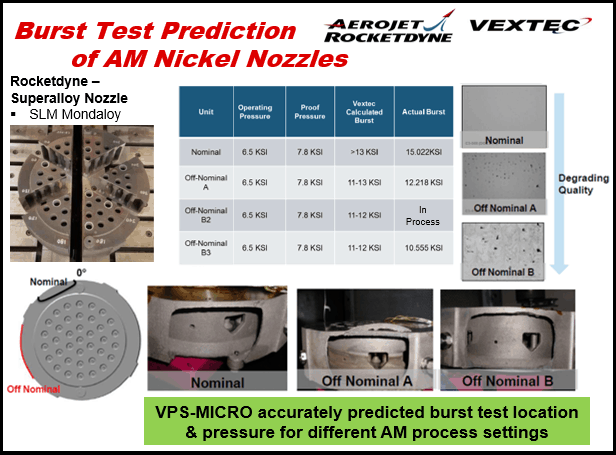

VEXTEC recently contributed to an Air Force research program on Selective Laser Melting (SLM) of the nickel superalloy Mondaloy, a desirable rocket engine material due to its tolerance of high-pressure gaseous oxygen. The research team, which included Aerojet Rocketdyne as the prime contractor, was tasked with creating models that link the variation in AM processing conditions to the microstructure of the resultant material. An extensive design of experiments matrix was conducted, to study the process sensitivity for off-nominal AM machine settings. A multitude of AM Mondaloy engine nozzles was built, each one having a different amount of defective material (representing different off-nominal machine parameter combinations).

VEXTEC was tasked with simulating failures from monotonic loading, and used these simulations in the static strength certification. Aerojet had performed a large number of microstructural observations of the various processing conditions. These data provided the inputs to VEXTEC’s VPS-MICRO simulations, to predict the probability of failure for the various microstructural conditions. It was only after the simulations were run, that Aerojet conducted the physical cyclic proof and bust tests of the nozzles. The failing burst pressure and the nozzle burst locations were accurately predicted by VPS-MICRO.

The future is bright for additive manufacturing, as well as for predictive durability modeling of additively manufactured components!

VEXTEC and AM: Built Together

Leave A Comment