Virtual Twin® Explained

Imagine having a digital copy of a mechanical component, a complex system – even an entire product line or fleet – that can be exercised through in-service or customer usage scenarios just as if it were actually present in the physical world.

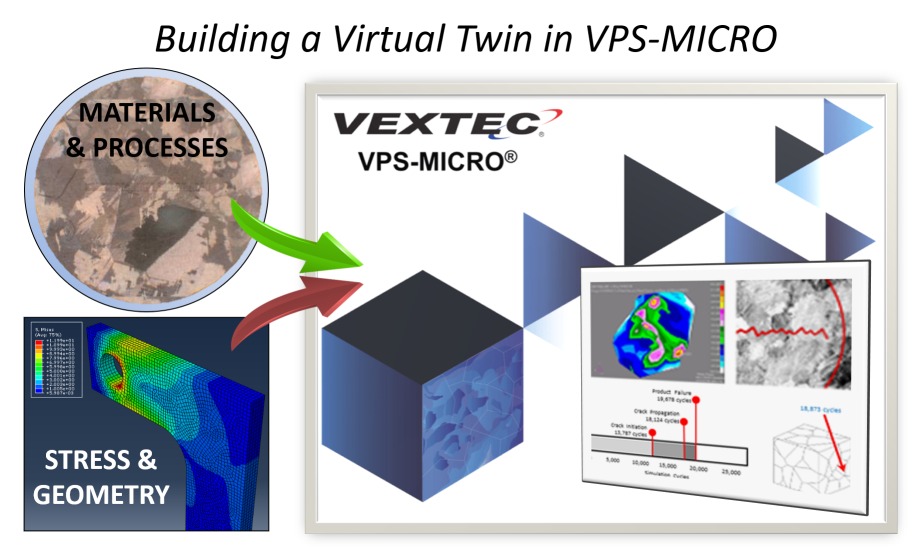

This is the principle behind VEXTEC’s Virtual Twin® simulation software: VPS-MICRO®.

The Virtual Twin in Use

If a component, product or system of components already exists, a Virtual Twin can be built in VPS-MICRO from the existing digital or even analog information that describes

its geometric dimensions;

its material properties (from physical samples or the parts themselves);

its manufacturing processes; and

usage or stress models.

If the component does NOT yet exist (i.e. still in the design stage), VPS-MICRO can be used to create a Virtual Twin representation based on whatever specifications the manufacturer selects. VEXTEC has even re-engineered designs customers’ legacy parts – using no more than a box of broken pieces.

Once a customer has built their Virtual Twin VPS-MICRO, they can run fatigue simulations based on the product as it exists today, or whatever design changes are being considered. Virtual Twins can be exercised through a number of different design, material, and manufacturing parameter settings within the software. The user decides which settings are appropriate, and then the software is ready to run.

VPS-MICRO has an easy-to-use interface that can directly “read-in” geometry and stress information from many commercially available FEA software packages (including ANSYS and Abaqus). Users can input different FEA models with little or no involvement from VEXTEC. As VPS-MICRO runs, tens of billions of microstructural-level simulations are conducted, cataloged and aggregated. The architecture of the software allows for these simulations to be conducted efficiently, reducing overall processing time to hours – or even minutes in many cases. After the simulations are complete, fatigue durability results can be tabulated, graphed, sorted, and exported for further post-processing.

Obtaining this type of product intelligence from a Virtual Twin simulation is simple and straightforward in VPS-MICRO. For example, a recent customer was able to isolate three factors that contributed to a turbine wheel’s reliability:

the size of grains in the material;

the processing defect density; and

the speed and variation in wheel cycles per day.

From these parameters, the software produced a dynamic model that showed the effects of adjusting each parameter in 1% increments for a fleet of 10,000 turbine wheels. To replicate the fidelity of those same results, the company’s research lab would have had to perform thousands of experiments for all 10,000 components, a physical impossibility.

For more information about how to build your own product’s Virtual Twin simulations in VPS-MICRO, contact us!