June 13, 2014 – Brentwood, TN — The Naval Air Systems Command has awarded a fourth contract to VEXTEC Corporation to help improve helicopter durability. Gearbox durability is an important part of helicopter safety and reliability.

VEXTEC is working with the Navy on ahelicopter tail gear box (TGB). The particular component under investigation is the shaft, which ispart of the transmission system that transfers torque to the tail rotor. The tail rotor counters the torque of the main rotor, and is essential for the pilot to control the aircraft. Fracture of the shaft will disrupt power to the tail rotor. During extreme operational conditions, fatigue cracks can initiate and grow in the shaft. The Navy has undertaken steps to determine the root cause of this cracking.

Once this has been determined, appropriate design changes will be made. The overall purpose of the program is to determine the crack growth rate of very small cracks propagating in the shafts under relevant operating conditions, and the expected spline durability once cracks initiate.

The program will provide essential data for fracture analysis. Specimens fabricated from an actual TGB shaft will be tested at representative mission flight loads to develop reliable crack propagation rate and stress intensity factor curves. The stress intensity factors determine what state of stress is sufficient to actively propagate a crack and how many cycles the shaft can survive before failure. Both of these quantities are strongly influenced by the actual fabrication process.

The Navy has been testing for the fatigue failure mode on the shafts under combined torsion and bending loads to isolate the failure cause and develop design improvements. VEXTEC is conducting additional fatigue crack growth tests on specimens cut from the shafts under variable mission loading conditions. The specimens are an arc sector of shafts that have been used in operation and have the geometry, residual stresses and surface condition of actual shafts. Traditional crack growth specimens are of simple rectangular geometry with machined large cracks. A test fixture has been designed and built to replicate the loading of the actual shaft in operation.

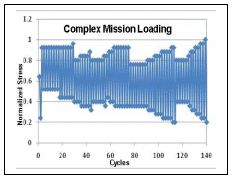

A major contributor to component durability is the mission load sequence that the component experiences in operation. In traditional crack growth testing, data is taken at constant amplitude load and the variable amplitude effects are not determined. The objective of this program is to determine the influence of mission overloads, offloads and sequence on the component material crack growth rate as well as the threshold loading for the crack to grow and the critical loading to cause fracture. This information is critically important since it determines the effect of operational loading on the shaft durability. Successful completion of this effort will provide reliable data to complement the fracture analysis.

A major contributor to component durability is the mission load sequence that the component experiences in operation. In traditional crack growth testing, data is taken at constant amplitude load and the variable amplitude effects are not determined. The objective of this program is to determine the influence of mission overloads, offloads and sequence on the component material crack growth rate as well as the threshold loading for the crack to grow and the critical loading to cause fracture. This information is critically important since it determines the effect of operational loading on the shaft durability. Successful completion of this effort will provide reliable data to complement the fracture analysis.

About VEXTEC:

VEXTEC was founded in 2000 and has developed its patented technology on

virtual material modeling and predicting product durability. VEXTEC offers its Virtual Life

Management (VLM) software and services to a variety of commercial and government customers.

Contact:

VEXTEC Corporation

Ashley C. Clark

Marketing Manager

(615) 372-0299 (ext. 233)

aclark@vextec.com

Leave A Comment