We previously discussed how corrosion can be “the good guy” for some applications when degradation is beneficial, such as in self-deteriorating medical implants. Also, how it can be “the bad guy” for some other applications where degradation impairs the structural integrity, like in airplane structures and oil and gas pipelines and vessels. As the bad guy, its impairing effect needs to be mitigated; and as the good guy, corrosion needs to be intentionally designed. Thus, both need to be managed and controlled. Corrosion control eats up time and money in both cases. Controlling corrosion, as the bad guy, has prompted manufacturers to develop a corrosion management system (CMS) to mitigate the effect of corrosion, since its global cost exceeded US$ 2.5 trillion in 2013 (3.4% of the global GDP). However, this CMS is not only applicable to unintended corrosion. It also can be adopted when corrosion is part of the design (the good guy). However, CMS requires advanced labs, massive amounts of data gathering and experiments, and years of experience, which in return consumes too much time and money.

We previously discussed how corrosion can be “the good guy” for some applications when degradation is beneficial, such as in self-deteriorating medical implants. Also, how it can be “the bad guy” for some other applications where degradation impairs the structural integrity, like in airplane structures and oil and gas pipelines and vessels. As the bad guy, its impairing effect needs to be mitigated; and as the good guy, corrosion needs to be intentionally designed. Thus, both need to be managed and controlled. Corrosion control eats up time and money in both cases. Controlling corrosion, as the bad guy, has prompted manufacturers to develop a corrosion management system (CMS) to mitigate the effect of corrosion, since its global cost exceeded US$ 2.5 trillion in 2013 (3.4% of the global GDP). However, this CMS is not only applicable to unintended corrosion. It also can be adopted when corrosion is part of the design (the good guy). However, CMS requires advanced labs, massive amounts of data gathering and experiments, and years of experience, which in return consumes too much time and money.

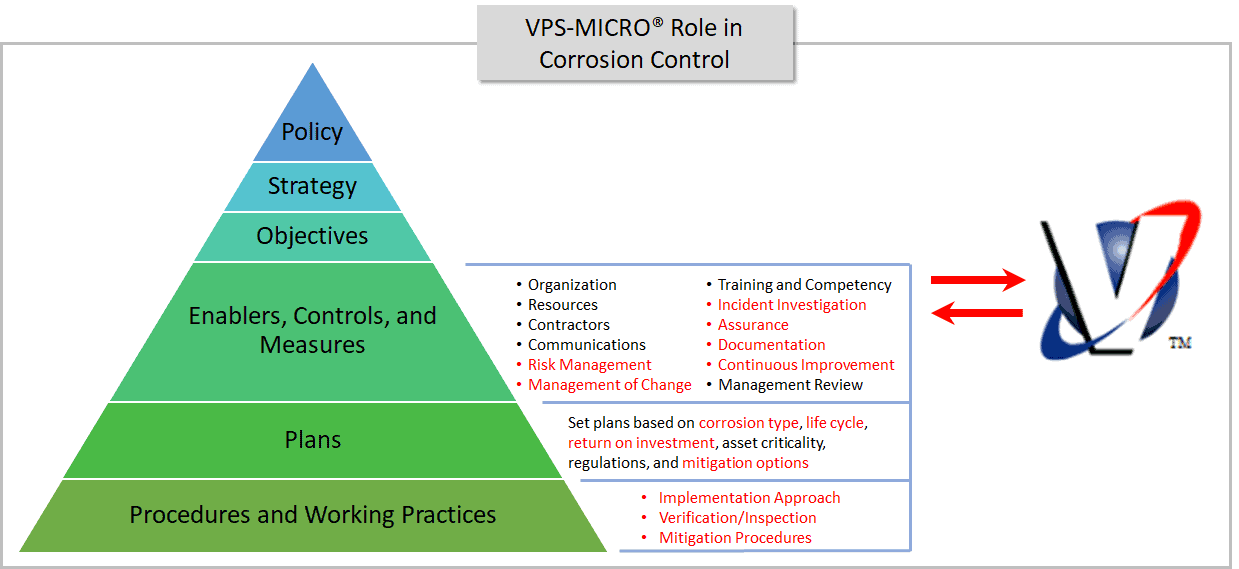

With regard to CMS, the National Association of Corrosion Engineers (NACE) proposed a hierarchical pyramid that can be implemented. The pyramid consists of many elements and procedures that span from upper management down to testing practices that are tailored to control corrosion. Corrosion alone is seldom the cause of degradation and failure. The structural failure is induced by manmade—controllable—factors such as dissimilar material galvanic corrosion, stress corrosion cracking and corrosion fatigue. Controlling corrosion means controlling those manmade factors. It is the combination of corrosion and loading that has been the dominant factor driving failure for many industries such as healthcare, oil and gas, weapon systems and infrastructure and aerospace. For example, the Department of Defense (DoD) estimated that its cost of unintended corrosion, that is mainly caused by corrosion fatigue, exceeded US$ 21 billion in 2010. Assessment of corrosion fatigue requires collecting a massive amount of information and data about the microscopic structure of the materials and their reliability. That requires years of experience and running a huge number of experimental tests. Consequently, huge amounts of time and money need to be spent in order to design, make decisions and implement action items. However, in the past few years, computer modelling in material science has advanced to the point that we can start to predict corrosion damage based on the underlying physics instead of relying on large test programs. Using integrated computational materials engineering (ICME), which combines industrial knowledge with physics, we can reduce the time and money needed for the decision-making process.

VEXTEC has developed the Virtual Twin® that predicts the probability of degradation down to the microstructural level, where damage starts. The latest version of VEXTEC’s software VPS-MICRO® provides a probabilistic physics-based assessment of materials exposed to corrosion fatigue. VPS-MICRO is a versatile software. The software combines our historical knowledge of corrosion and fatigue with physics-based computations. It is multifunctional and can interact with the different elements of a corrosion management system depending on the type of requested results. Engaging VPS-MICRO as a Virtual Twin can provide a time and cost-efficient evaluation of new or existing materials and designs. It not only reduces the corrosion control cost, but it increases the return on investment; less amount of experimental testing, faster evaluation, and less hassle during the decision-making process. The technology adopted in VPS-MICRO will be discussed in the concluding blog in this series.

Leave A Comment