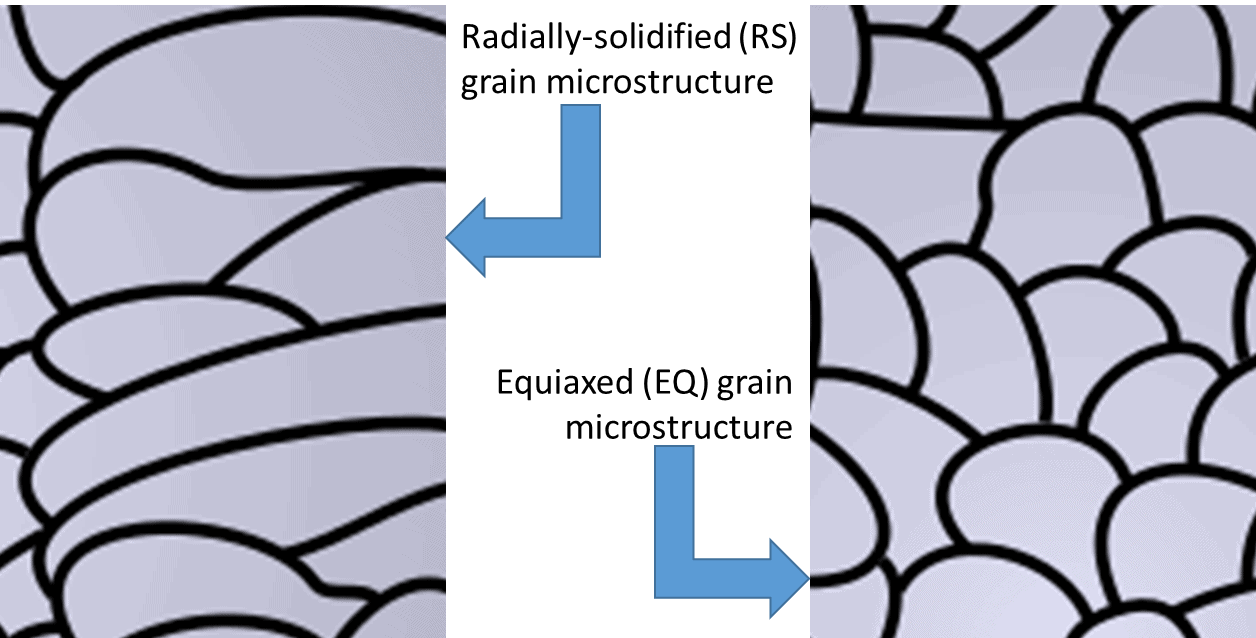

A turbocharger client of ours wanted to improve durability and reduce warranty costs on cast wheels made from a nickel superalloy with a radially-solidified (RS) microstructure. A significant portion of their previous field failures had been attributed to high cycle fatigue (HCF). Our client already had ideas about how to reduce these HCF failures by changing the wheel’s microstructure to an equiaxed (EQ) morphology. General representations of RS and EQ microstructures are shown here.

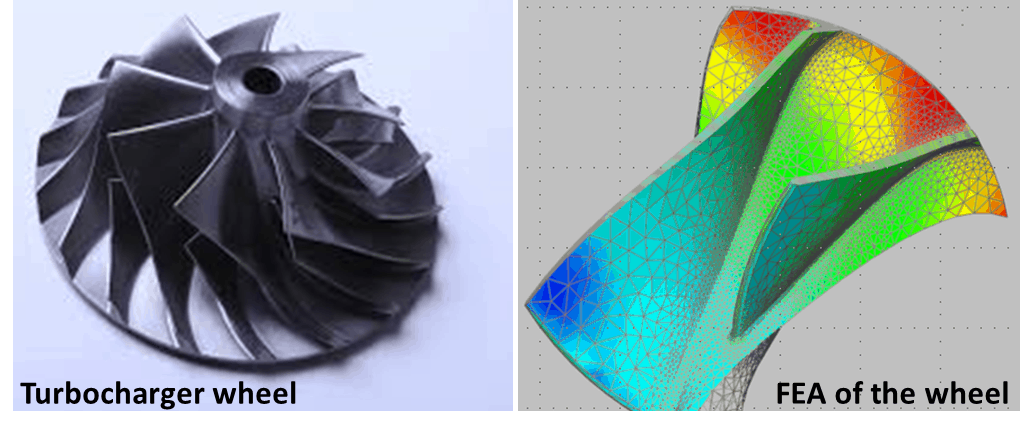

Since design changes like these would require a hefty amount of physical validation testing, they needed a way to predictively quantify the costs/benefits to the product line, should some of these proposed changes be implemented. So they turned to VPS-MICRO®. The VPS-MICRO simulation platform combines structural finite element analysis of the component (FEA, seen below) with a 3-D spatial model of the material’s microstructure to predict component durability risk. It is a probabilistic framework, accounting for variability in microstructure and strength properties, applicable damage mechanisms, and usage over time.

The primary inputs to VPS-MICRO are the design input file (stresses from the FEA and the corresponding stressed area in terms of elemental surface area) and the material input file. VEXTEC has developed plug-ins to extract the design input information from several commercial FEA software programs. The material input file contains all the relevant material properties of the component, from macro-scale to the microstructural level. These properties include those you would normally find in an FEA analysis (material modulus and Poisson’s ratio), but also microstructural properties such as grain size, population density of variously-sized inclusions/defects, and grain-level strength and energy parameters. It is the inherent variability of these microstructural properties that is a key factor of component-level fatigue life variability. The good news is that these properties can be statistically evaluated using industry standard (ASTM) tests.

Now, back to our client’s specific issue. Their RS material microstructure was originally developed to resist the onset of damage at high temperatures. The likelihood of initiating damage is low due to fewer grain boundaries. However once damage initiates, the failure probability goes up because there aren’t as many grain boundaries to arrest crack growth. Their proposed design change, using an equiaxed (EQ) microstructure instead for the turbocharger wheels, was thought to be more damage tolerant. The likelihood of initiating damage would be higher, but so would the opportunity for fatigue crack arrest (more grain boundaries). Using VPS-MICRO, our client was able to pursue a quantitative assessment of the risk of HCF failure versus grain type (radially-solidified vs. equiaxed), before any re-designed wheels were even produced or tested.

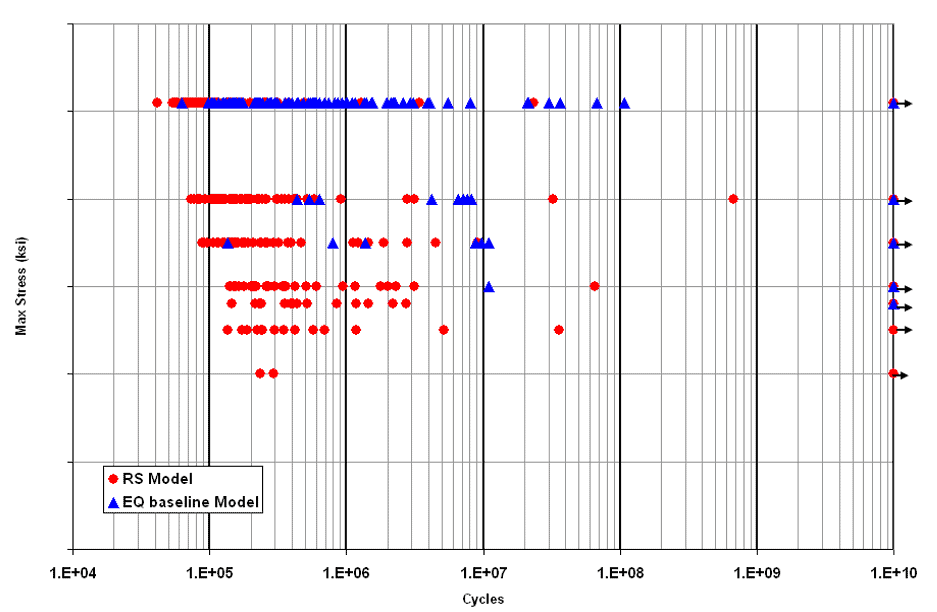

Shown below is the VPS-MICRO simulated fatigue life comparison of the current-state RS wheel, and the proposed EQ wheel (baseline average grain size = 2.7 mils). The comparison results are presented using a simulated S-N (Stress-Life) plot. The figure shows considerable variability at each stress level for both materials. Run-outs (the points on the right marked with arrows) are predicted at every stress level. A “run-out” means the simulated specimen did not fail within the number of cycles analyzed. These results indicate the RS wheel would have a lower endurance (fatigue limit) compared to the baseline EQ wheel. Generally speaking, this would seem to indicate that the EQ material is better than the RS material. These results appeared to correlate with published industry reports.

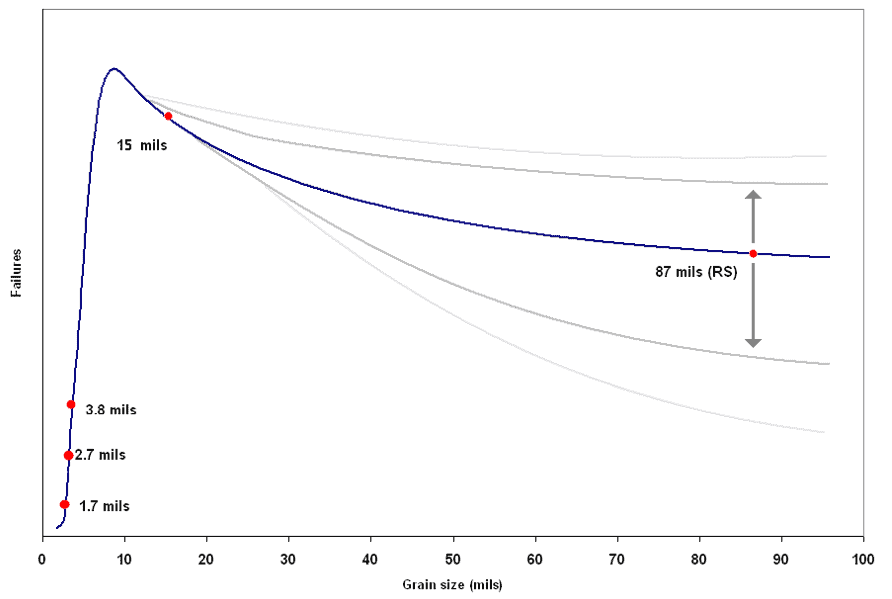

Because the wheel was a casting, there is an expected grain size variation throughout the part. Our client’s quality group thought they could maintain the EQ grain size between 1.7 and 3.8 mils, but acknowledged that sizes as high as 15 mils could occur. So they used VPS-MICRO in a different way: to evaluate the sensitivity of grain size to the risk of wheel failure. Their virtual analysis revealed that EQ wheels are not always better than RS wheels. The figure below shows that failure probability is low for small EQ grains, but is very sensitive to grain size. At a grain size of 15 mils, the EQ wheel is actually more likely to fail than the RS wheel (which has an average grain size of 87 mils). Probability of failure is not as sensitive to grain size for the RS wheel. Did the reversing trend make sense?

VEXTEC and our turbocharger client investigated this relationship between the grain size and HCF failure risk. After analyzing the output of the VPS-MICRO simulations, we determined that competing failure mechanisms were present:

- The area effect: it takes more small-sized grains to fill a given surface area compared to fewer, larger grains. A smaller average grain size means a statistically-higher probability of having a weaker grain in a given area. This is analogous to the “weakest link theory“, where increasing the number of links in a chain increases its probability of failure. This explains why larger grains are producing fewer failures compared to small grains (the downward trend of the figure above).

- The grain-level strength effect: as the grain size increases, an initiating fatigue crack has a larger size as well. These larger-sized starter cracks are more likely to grow (with minimal arresting) to final failure. Therefore, the local strength properties of the grains become key gatekeepers to either prevent or allow these cracks to propagate from their initial sizes.

The final conclusions reached by our client, with the assistance of VPS-MICRO, were

- Using EQ material (2.7 mils) would reduce turbocharger wheel HCF failures by at least 60%

- Not all EQ materials are equal; small changes in grain size yield large changes in durability

- The probability of wheel failure was not as sensitive to grain size for the RS material

- Replacing RS material with EQ material requires significantly-tighter production control

Our client could now make a more-informed decision about the proposed design change (producing and testing the EQ wheel). They knew they would have to cast the wheel in a production environment to capture realistic variations, and to assess their capability to hold tighter tolerance on grain size than what was previously required on the RS wheel.

We’ve said it before, and we’ll say it again:

Leave A Comment