Most people probably remember the TV show CSI: Crime Scene Investigation. One of the more popular “police procedural” television franchises in the recent past, CSI: (and its similarly named spin-off shows) differentiated itself by giving the crime scene’s evidence the starring role. Much of the drama in the show centered on how it painstakingly built the investigation process – understanding the “how” and the “why” – instead of focusing on the “what”. Rather than relying on intuition, investigators pieced together the physical evidence throughout the program, leading to witnesses, suspects, motives, locations, and timelines. Often, high-tech instruments would be used in the crime lab to analyze things like blood traces or bullet casings. Reports would be written which would then be used in the arrest and conviction of the perps, or conversely, to exonerate the wrongly-accused.

While real life crime scene forensic analysis may not always be as glamorous/gory as it’s depicted in Hollywood, distinct parallels can be drawn between the procedures involved in dissecting a crime scene and those used in component failure analysis. In fact, the term Forensic Engineering is used to describe the investigation of physical failures. And Forensic Materials Engineering categorizes the methods used and processes followed to study why structures and materials fail and who (or what) could have been at fault. As they say, it’s usually not good enough to determine when something broke (i.e. “number of fatigue cycles to failure”); the most interesting information comes as answers to the questions of how it broke (failure mechanisms) and why it broke (external conditions). A thorough failure analysis can answer all of these questions and more.

When manufacturing companies receive broken components from their end users (known as “field returns” or “field failures”), those components will usually go through a level of laboratory process very similar to a crime scene investigation. All available evidence will be collected, documented and analyzed, using both high-tech and low-tech instruments (tabletop light microscopes for metallography, scanning electron microscopes [SEM] for fractography, chemical analysis, etc.). Traditionally, these tests can be time-consuming, and as with any CSI time is of the essence (as well as efficiency and accuracy). Finally, reports will be produced to justify the conclusions made from the analyses. If a company is well-integrated, these failure reports will act as feedback to the design and materials teams on the front end of product lifecycle management (PLM). This would hopefully point out flaws that may have been missed during the original development activities, and bring about continuous improvement in the product. The insights can better inform the qualification testing testing procedures, so that reliability can be more realistically assessed. However, this feedback process can also take a lot of time because the field failures first have to occur, be reported, be adequately analyzed, and then results have to make their way to the proper teams in the organization. Wouldn’t it be more effective for there to be a way to perform this analysis beforehand, and help make the product better before it even has a chance to fail?

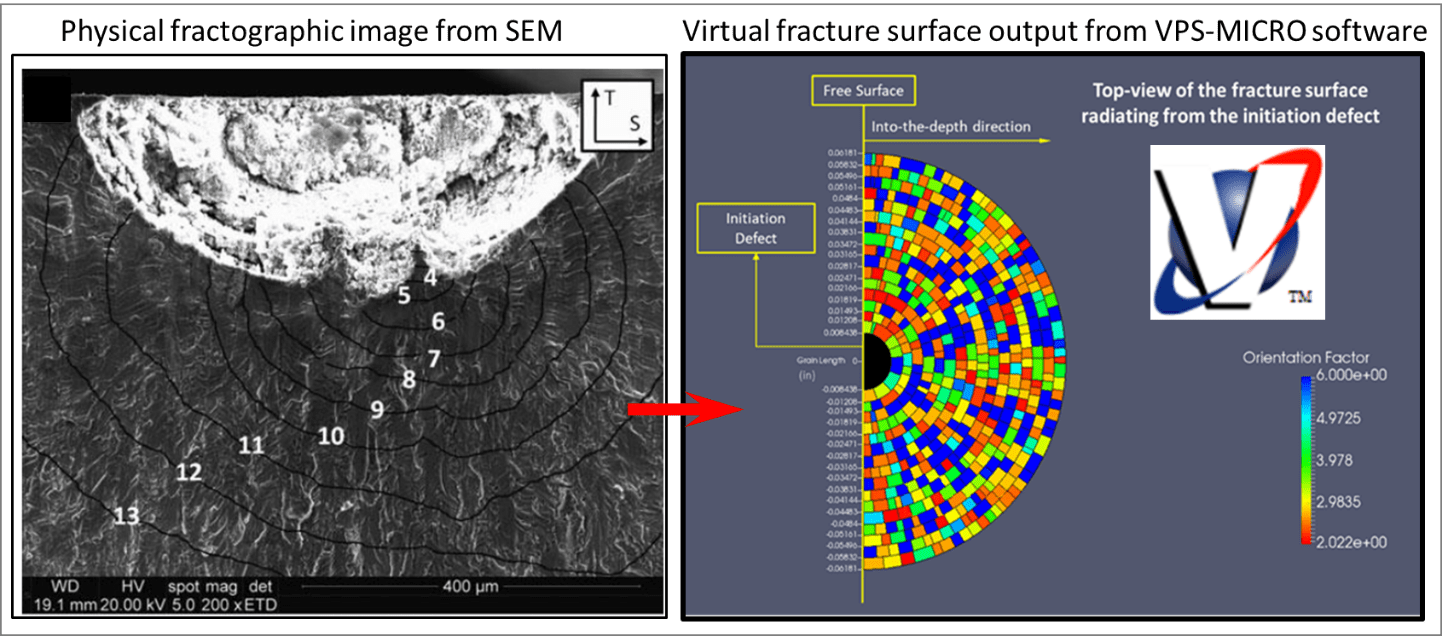

VEXTEC’s VPS-MICRO® software functions as a computational forensic engineering tool. By inputting component design and material information, you can virtually perform field tests of your parts under many different circumstances and conditions, with varying material capabilities. When the simulations complete, the output answer is not simply the predicted number of cycles to failure (the typical result of the prevalent fatigue estimation software packages around), but it also provides the entire digital trail of evidence that led to that failure. Each of the images below represents fatigue crack damage emanating from an initial defect; physical evidence on the left, and a computational simulation output of the damage from VPS-MICRO on the right. The physical evidence can show you where something failed, and after enough in-depth analysis, can give an idea of fatigue crack growth rate (da/dN). The simulation results on the right are even more informative, providing details such as crack growth (a vs. N), grain individual orientation, localized stresses, and microcracking. These simulation outputs capture the variability inherent in fatigue testing, and give quantitative evaluation of the likelihood of such events.

You can investigate the initiation mechanisms of the damage (whether they be from non-metallic defects, rogue large grains in the microstructure, surface roughness, etc.), and follow the damage right through to failure. The locations, motives, timelines, and suspects of component failure are all studied in the virtual realm, at a fraction of the time spent in physical test labs, reducing risk to end use customers as well as risk to important company metrics like PLM and warranty budgets. Just as “persons of interest” can be vindicated and set-free by the physical evidence that is found and properly processed, the predictive models used in VPS-MICRO can validated by comparison to results from a limited amount of physical testing. Once this verification and validation (V&V) activity is complete, the software can be used for a multitude of product design trade studies (geometrical effects, material second sourcing, manufacturing process changes). The evidence is still the star of the show here, and VEXTEC has added another high-tech resource to the CSI engineering toolbox!

You can investigate the initiation mechanisms of the damage (whether they be from non-metallic defects, rogue large grains in the microstructure, surface roughness, etc.), and follow the damage right through to failure. The locations, motives, timelines, and suspects of component failure are all studied in the virtual realm, at a fraction of the time spent in physical test labs, reducing risk to end use customers as well as risk to important company metrics like PLM and warranty budgets. Just as “persons of interest” can be vindicated and set-free by the physical evidence that is found and properly processed, the predictive models used in VPS-MICRO can validated by comparison to results from a limited amount of physical testing. Once this verification and validation (V&V) activity is complete, the software can be used for a multitude of product design trade studies (geometrical effects, material second sourcing, manufacturing process changes). The evidence is still the star of the show here, and VEXTEC has added another high-tech resource to the CSI engineering toolbox!

Leave A Comment