In additive manufacturing (AM), there are many potential benefits for cost savings, among them being

• integration of many conventional components into a single AM build;

• complex shapes and orientations;

• product volume control (short runs for sustainment vs. longer runs for new production); and

• limited post-build machining.

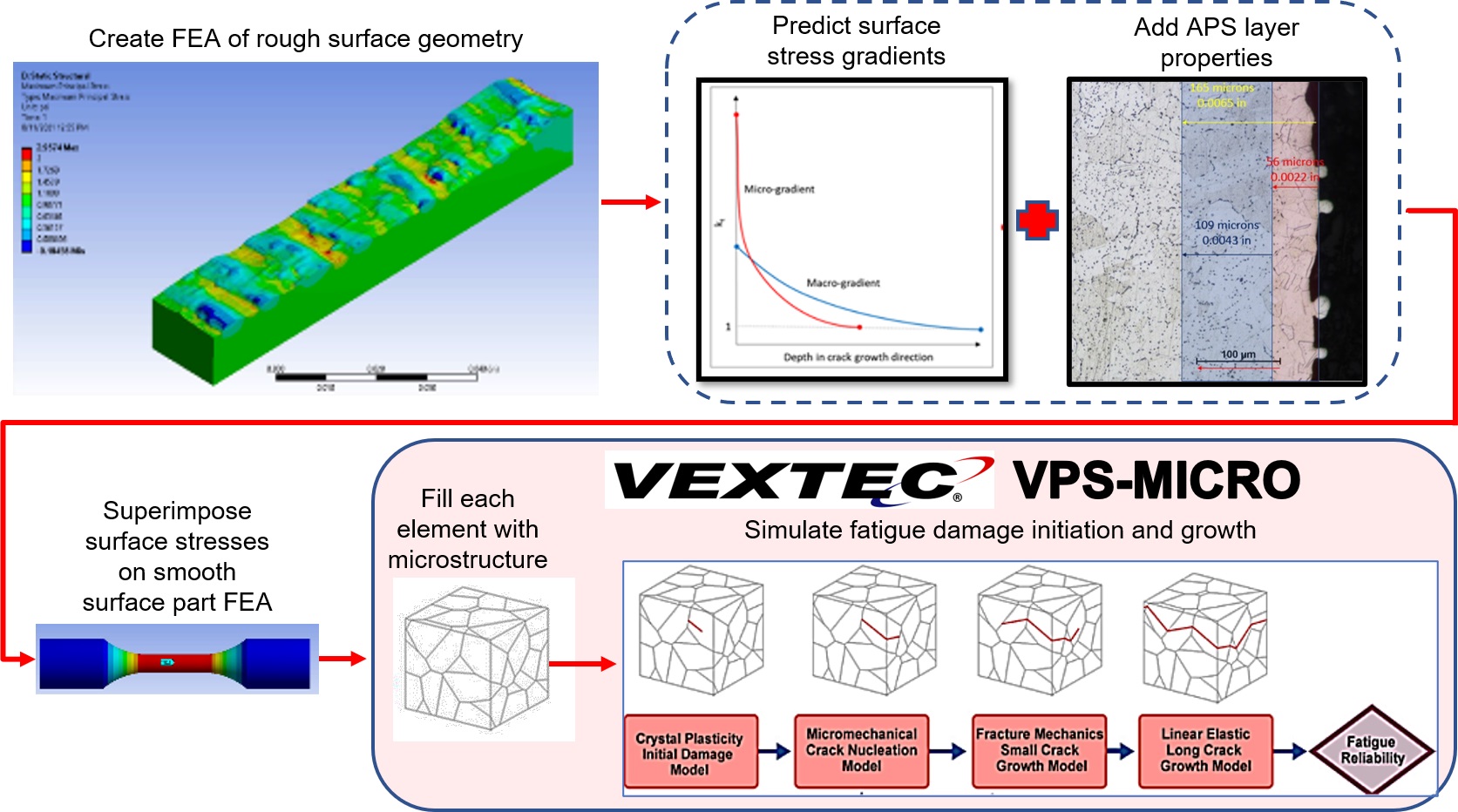

AM can bring 30-60% cost savings on complex, high-value parts in the aerospace industry. The limited post-build machining aspect is particularly attractive, in that it can eliminate many steps between production and end-use. As much as 20% of a part’s cost can be incurred during post-build machining to remove surface roughness effects. Another major potential for savings is reducing part count in complex assemblies, which creates internal and other hard-to-access surfaces that cannot be machined. Therefore, it is advantageous to computationally predict the impact of an AM as-printed surface (APS) on fatigue performance for metal parts. This can be done using our VPS-MICRO predictive software, by differentiating the APS from the machined surface in terms of stress and material properties.

While VPS-MICRO does not explicitly perform AM process modeling, it can model the effects on fatigue performance that result from a wide range of manufacturing processes such as surface roughness, residual stress, and heat treatment layers (carburizing, nitriding, etc.). The roughness due to APS typically comes from features like raised bumps due to AM powder unmelt, as well as extensive crevices (which likely exist along microstructural grain boundaries). These features can be effectively evaluated and measured using microscopy and/or serial sectioning.

While VPS-MICRO does not explicitly perform AM process modeling, it can model the effects on fatigue performance that result from a wide range of manufacturing processes such as surface roughness, residual stress, and heat treatment layers (carburizing, nitriding, etc.). The roughness due to APS typically comes from features like raised bumps due to AM powder unmelt, as well as extensive crevices (which likely exist along microstructural grain boundaries). These features can be effectively evaluated and measured using microscopy and/or serial sectioning.

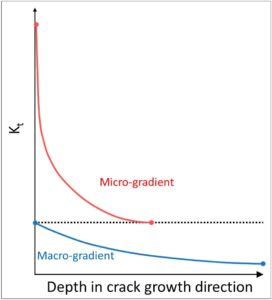

After measuring these APS features, a 3D spatially varying probabilistic structural finite element analysis (FEA) can then be used to statistically model the stress effects from the features – some act as stress concentrations of undulating peaks and valleys, others act as sharp crack-like stress intensities. These can be represented by stress gradients which act on different size scales (micro-gradients and macro-gradients). It is the interactions between the stress concentrations and the stress intensities that contribute to fatigue crack nucleation and small flaw growth at the rough surface. These gradients from the FEA are direct inputs into VPS-MICRO.

After measuring these APS features, a 3D spatially varying probabilistic structural finite element analysis (FEA) can then be used to statistically model the stress effects from the features – some act as stress concentrations of undulating peaks and valleys, others act as sharp crack-like stress intensities. These can be represented by stress gradients which act on different size scales (micro-gradients and macro-gradients). It is the interactions between the stress concentrations and the stress intensities that contribute to fatigue crack nucleation and small flaw growth at the rough surface. These gradients from the FEA are direct inputs into VPS-MICRO.

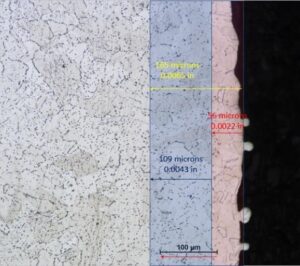

Other contributing factors to fatigue of APS parts are found in the microstructure of the APS material itself. There can be material properties in the surface layer that are not found in the material’s core: voids of different sizes and shapes, depleted amounts of precipitates like carbides, etc. The core microstructure will be similar to the material of a smooth specimen (the APS being machined away). These layer differences can cause variations in local strength properties. While collecting the surface layer microstructural properties can be challenging, there are microcopy techniques available to assist. VPS-MICRO allows for input of multiple material layers, to effectively model these microstructural gradients.

Other contributing factors to fatigue of APS parts are found in the microstructure of the APS material itself. There can be material properties in the surface layer that are not found in the material’s core: voids of different sizes and shapes, depleted amounts of precipitates like carbides, etc. The core microstructure will be similar to the material of a smooth specimen (the APS being machined away). These layer differences can cause variations in local strength properties. While collecting the surface layer microstructural properties can be challenging, there are microcopy techniques available to assist. VPS-MICRO allows for input of multiple material layers, to effectively model these microstructural gradients.

The previously mentioned APS features can then be overlaid onto a standard VPS-MICRO analysis of a smooth, machined specimen. The resulting simulations provide quantitative information about how much fatigue debit there would be if the APS layer was not machined away. This type of computational analysis can help to avoid the “build-test-fail-repeat” iterative cycle that expends valuable resources during certification of an AM as-printed component.

Leave A Comment