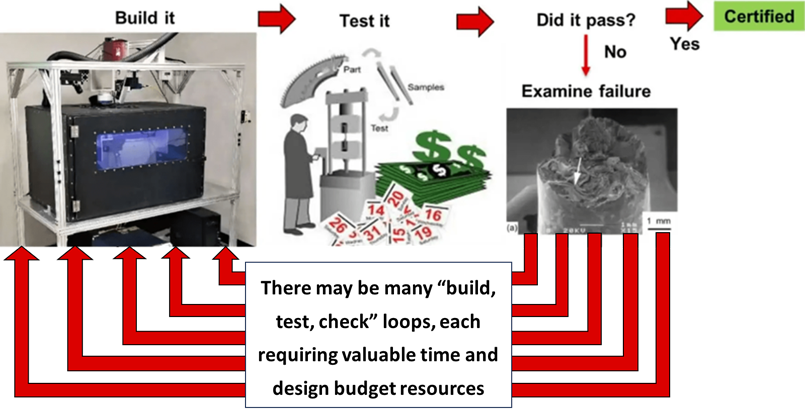

Current State of AM

The current AM development / validation process of build, test, analyze, repeat is iterative, costly and slow.

This results in long lead times and high development costs.

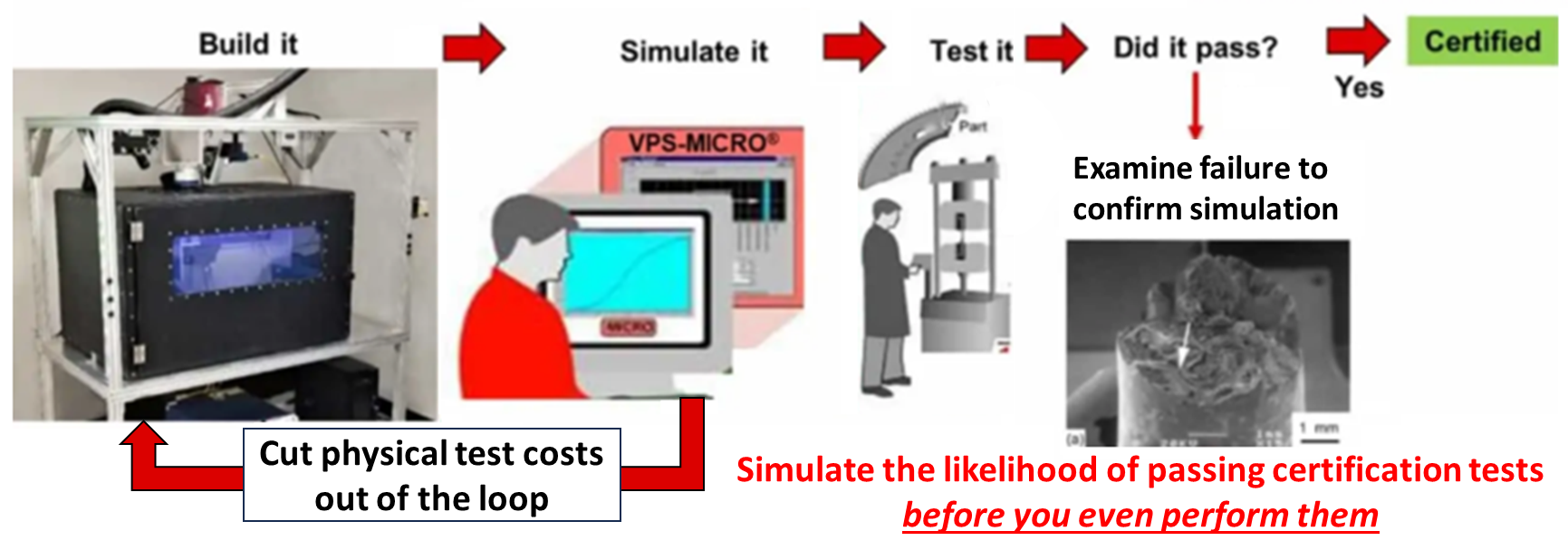

AM with VPS-MICRO

The Integrated Computational Materials Engineering (ICME) tool VPS-MICRO® can provide SIGNIFICANT COST/TIME SAVINGS for AM process development.

Simulating first with VPS-MICRO ® software conserves valuable testing resources, getting you to the answers that you need faster.

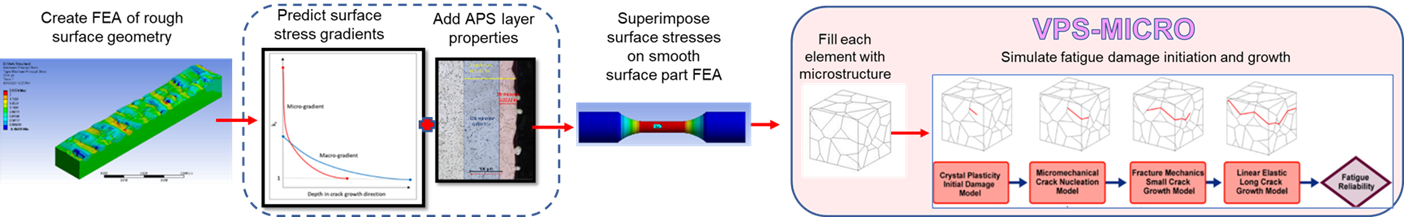

VPS-MICRO Can Evaluate Impact of AM Surface Roughness

VPS-MICRO has enhanced capabilities to accurately predict fatigue performance of metal AM parts with as-printed surfaces (APS). One critical APS feature is surface roughness, which can take the forms of sharp crevices and pits (acting as stress concentrations at the micro scale level) as well as undulations due to change in build/print orientation (again, acting as stress concentrations at the macro scale level). VEXTEC has developed standard protocols to spatially model these as 3D random stress gradients at both size scales, augmenting traditional FEA structural analysis techniques. Another critical APS feature is the presence of a gradient microstructure, where the surface layers of a component may have distinctly different compositions and properties compared to its core. VPS-MICRO’s ability to vary the microstructural modeling on the surface and into the depth makes for a powerful tool that captures the true variability seen in AM parts (part-to-part, and within one part). VPS-MICRO can also be utilized to optimize any post-build selective machining activities.

Federal Programs Using VPS-MICRO® For Additive Manufacturing Process Development

The goal of VEXTEC’s AFWERX Phase II SBIR is to combine limited physical testing with computational modeling, to predict the reliability of a primary structure built via a large-format AM process such as wire DED. VEXTEC is collaborating with AFRL/RQ and OEM supplier Lockheed Martin to identify an appropriate process and material alloy, and will demonstrate the feasibility of utilizing computational microstructural simulation to reduce the large physical testing database required to produce confidence in AM primary structure product performance.

VEXTEC worked with the Air Force Life Cycle Management Center during a prior Phase II program, using VPS-MICRO to assess the risk of failure for replacing a legacy manufactured turbine engine fuel linkage bell crank with an AM bell crank. This program demonstrated a digital engineering certification process to reduce the testing required to qualify a LPBF component for sustainment, and resulted in VPS-MICRO software deployment and training to Tinker Air Force Base personnel.

A Phase III follow-on program focused on VEXTEC working with engineers at AFRL/RQ to deploy and utilize VPS-MICRO for evaluation of powder DED repair techniques for engine airfoils.

In this AFRL SBIR, computational models were developed for VPS-MICRO that predicted the fatigue life debit of AM components due to APS features. Additionally, a scheme was proposed to integrate these digital engineering models within existing schemes for certifying AM components. The tool was calibrated and validated with a statistically large number of laboratory fatigue tests of LPBF specimens performed by our OEM partner, Aerojet Rocketdyne. The model simulations predicted the statistical distribution of the nucleated crack sizes, the number of cycles to nucleate cracks and their subsequent growth as short and long cracks. The model is unique because it simulates the interaction between the surface roughness and the material’s microstructure.

VEXTEC was awarded a small business innovative research (SBIR) contract, supported by Aerojet Rocketdyne, to develop an additive manufacturing certification framework for Air Force applications, with the objective of accelerating the qualification and adoption process for new additive manufactured (AM) materials, augmenting the traditional verification process with a model-informed software tool called VPS-MICRO. The program will leverage microstructural data to create a digital model that can be used to predict the critical fatigue failure points of a component and simulate how surface features affect overall component strength. The goal is to have a mix of physical test data combined with virtual data to accelerate the qualification process. Aerojet Rocketdyne will provide years of historical test data and VEXTEC will provide the software modeling capability.

Under the Phase II program, VEXTEC will lead a collaborative team from Universal Technology Company (UTC) and University of Dayton Research Institute (UDRI), further enhancing its VPS-MICRO predictive durability software to meet the challenges of additive manufacturing (AM). The Air Force needs a path to efficiently scale AM to realize maximum gains with regards to sustainment and fleet readiness objectives. The software framework will link: AM process information, AM in-situ sensors and Stress analysis and damage tolerance simulations. Specifically, this tool will help in (1) AM Process Development, (2) Outside Vendor Qualification/Process Control, and (3) Air-worthiness Certification.

This STTR program was a VEXTEC-led effort working with the University of Tennessee and Oak Ridge National Laboratory to develop a computational materials engineering software tool to decrease the time and money needed to certify an AM component for structural application. The powder EBAM process was used to create blocks of material with several types of microstructures. Four-point bend fatigue specimens were cut from the blocks, material microstructures were fully characterized, and fatigue tests were performed. Parallel to building the AM specimens and gathering the data, computational material models of the specimens were created. The fatigue lives were predicted using VPS-MICRO and compared well with the actual test results.